-

-

CL Solutions

Cathodoluminescence solutions that reveal fundamental properties of matter

-

Cryo Solutions

Integrated and automated solutions to u nlock the power of cryo - ET workflow -

FAST IMAGING

Fast EM solutions for reliable and high throughput electron microscopy

-

CLEM Solutions

Integrated correlative microscopy solutions that combine the power of fluorescence and electron microscopy

-

CL Solutions

- Contact

- All resources

-

CL Solutions

Cathodoluminescence solutions that reveal fundamental properties of matter

-

Cryo Solutions

Integrated and automated solutions to u nlock the power of cryo - ET workflow -

FAST IMAGING

Fast EM solutions for reliable and high throughput electron microscopy

-

CLEM Solutions

Integrated correlative microscopy solutions that combine the power of fluorescence and electron microscopy

Cryo Solutions

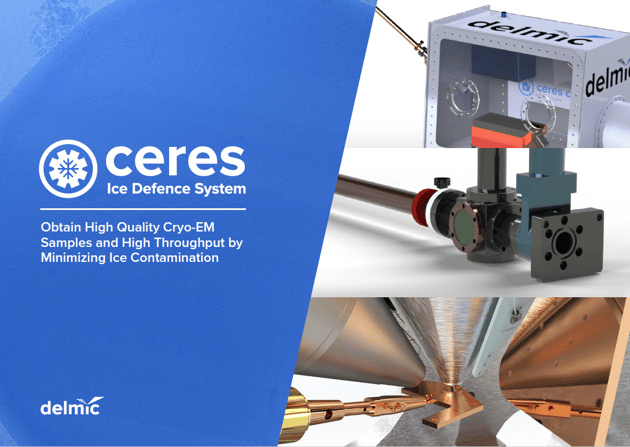

CERES Ice Defence System: frequently asked questions

Learn more about the specifications of our CERES Ice Defence System.

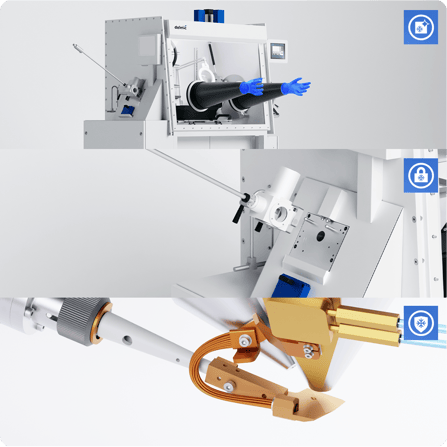

CERES Ice Defence System

-

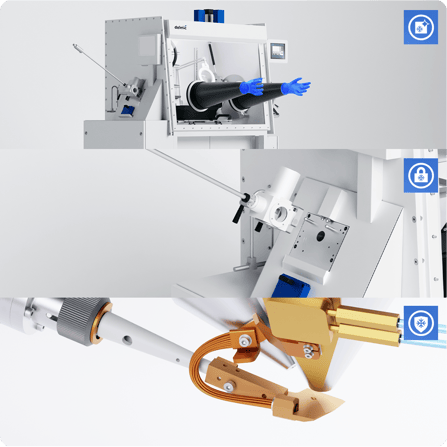

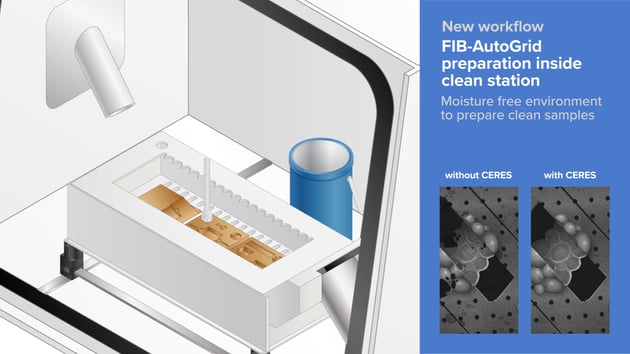

Why do I need CERES Ice Defence System?

Ice contamination can happen in various steps of the cryo-EM workflow whenever moisture in the sample environment condenses onto the cryo-sample, during sample preparation, sample transfers and even lamella generation. CERES Ice Defence System is aimed at avoiding the devastating consequences of undesired contamination, such as obscuring rare events and wasting samples that take weeks to prepare, or even precious human patient samples. The series of innovative tools, CERES Clean Station, CERES Vitri-Lock and CERES Ice Shield, used together or independently will help you obtain the highest quality cryo-EM and Cryo-ET samples, with higher throughput and world-class results.

-

How do I complete secured seamless transfers and keep my samples uncontaminated using CERES Ice Defence System?

With the sample loaded onto the shuttle module of the Clean Station, use the Vitri-Lock to retrieve the sample and transport it to the focused ion beam/scanning electron microscope (FIB/SEM) for milling and correlation using METEOR. The interior chamber of Vitri-Lock is cooled to keep your sample from devitrification. After the milling is complete, use the Vitri-Lock again to transport the delicate sample from the FIB/SEM to the Clean Station. Once the Vitri-Lock is mounted and the pressure is equalized, transfer the sample from the shuttle into an autoloader cassette using the cassette-loading module. The loaded cassette can then be moved to a Nanocab which is already mounted to the side of the preparation station. With the Nanocab loaded and ready for transport to the cryogenic transmission electron microscope (cryo-TEM), open the interior door of the right side airlock, and place the Nanocab on the sliding metal table. The interior door can then be closed and the exterior door opened allowing for final transport to the TEM.

CERES Clean Station

-

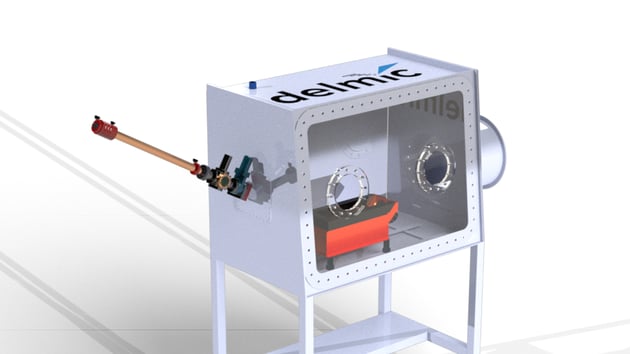

What are the differences between a low-humidity room, a glove box and CERES Clean Station?

CERES Clean Station has the highest success rate of preparing usable cryo samples. A pricey low-humidity room only guarantees medium cryo sample protection with high energy consumption and a cheap glove box is not intended to reduce moisture at all, whereas CERES Clean Station controls the humidity level to less than 100 ppm water while consuming low energy and low cost. In addition, the Clean Station is easy to install, move and use. Overall, the CERES Clean Station is the most cost-effective, user-friendly and environmentally friendly sample preparation platform to date.

-

Are the gloves reusable? How can we replace them?

Yes. The CERES Clean Station utilizes a modular glove/sleeve system. This allows you to utilize many of your favourite gloves. Ultimately, this will give you more flexibility and comfort while working with small and delicate samples.

-

When you bring your grids in a liquid nitrogen (LN2) dewar into the airlock, do you have to open up one side, put the little dewar in, close it up and vacuum down? How does it work?

The airlock exterior door is opened, the stainless-steel sample tray extended, and the LN2 dewar loaded onto the tray. The tray is then retracted into the airlock, the exterior door closed, and a rough vacuum applied. After a rough vacuum has been achieved, the space is then backfilled with dry nitrogen gas. This cycling process is repeated (automatically) until the desired H20 level is achieved, after which the user will open the interior door of the air lock and extend the sample tray into the interior of the Clean Station.

-

How many litres of nitrogen does the Clean Station need to use and would I need to keep cylinders of gas in my lab?

Nitrogen gas usage will vary widely as usage and ambient humidity are two large factors.

-

Is the Clean Station compatible with high-pressure frozen (HPF) samples?

Yes. The benefits of the Clean Station in a typical HPF workflow will depend on how the user is manipulating and loading their samples into a FIB/SEM. Typically the lift-out workflow using a sample shuttle to hold a HPF sample in one slot, and a half moon grid in another slot, which receives the lift-out chunk for thinning, is compatible with the CERES Clean Station. Please contact us for more information on how Clean Station could take your HPF workflow to the next level!

-

In which stage do the samples go into the glovebox? Pre-freezing or post-freezing?

Post-freezing. The configuration and features of the Clean Station lend themselves to protecting your delicate frozen samples during all stages of the post-vitrification imaging pipeline.

-

Can I move the Clean Station from room to room in my lab?

Yes. This is one of the primary benefits of having a mobile ultra-low humidity preparation station. The high-quality caster wheels provide easy, stable transportation through your lab.

-

I already have a ThermoFisher transfer stick, is this compatible with the Clean Station?

Yes. As of now, the Clean Station is compatible with both ThermoFisher and Delmic's own CERES Vitri-lock. However, we can likely adapt the Clean Station to work with any transfer device. Contact us for more information.

Learn more about the Clean Station on the product page

-

How do I supply the Clean Station with liquid nitrogen?

The Clean Station will accept connections to most of the commercially available pressurized liquid nitrogen dewars. Just letyour salesperson know the connection type of your dewar.

-

If I am transferring samples in through the multi-purpose airlock, how do I ensure the liquid nitrogen will not boil off during vacuuming?

When bringing in samples with liquid nitrogen through this port, you can simply use nitrogen gas flushing to achieve the required moisture content prior to introducing it into the interior of the Clean Station.

CERES Vitri-Lock

- What type of vacuum pump will I need for the CERES Vitri-lock and Clean Station?

-

How long does the Vitri-Lock ensure my samples stay vitrified for?

Your cryo sample will be protected against devitrification for up to 30 minutes. To learn more usage and features of the Vitri-Lock, we recommend reading this blog.

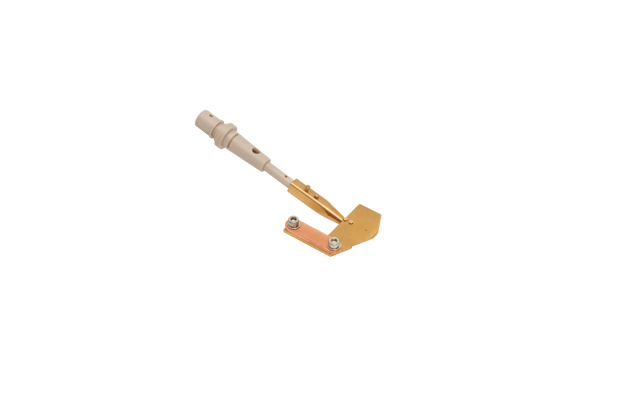

CERES Ice Shield

-

To what degree does the CERES Ice Shield prevent residual moisture in the chamber to condense on my lamellae?

The CERES Ice Shield can secure a >10-fold decrease in ice contamination rate. According to the test results at the Raunser lab at Max Planck Institute of Molecular Physiology, Dortmund, Germany (MPI Dortmund), the contamination inside the cryo-FIB/SEM becomes non-measurable.

Read the customer story of MPI Dortmund.

-

Is there an alignment procedure for the cryo shutter?

Our engineer performs the alignment at the time of the installation. After that there should be no need for realignment unless the user physically altered the cryo shutter orientation. In case a re-alignment is needed, a Delmic engineer will assist first of all remotely, or an on-site visit if needed. An alignment check is performed at the annual service visit as part of the service contract.

-

What is the purpose of the holes on the cryo shutter?

The Delmic CERES Ice Shield cryo shutter only has one hole. The hole is for the FIB. This is so we can perform lamella milling while protecting the sample from as much line of sight as possible from the SEM pole piece.

-

With long periods of use, is ice accumulation on either the Cryo Shield or the Cryo Shutter a concern?

No. In fact, by the time the shutter and/or shield reach room temperature, they are clean enough for re-use.

-

Is the long term cooling power of the Ice Shield reduced by contamination accumulation on its surface?

No. Long term accumulation is not a concern.

-

The cryo shutter arm needs to be retracted during the use of the electron column. Can this be automated or tied into the EM operation?

Yes. The cryo shutter automatically retracts when SEM imaging takes place. During rough milling periods, users can trust that the shutter will not impede their workflow. User can also manually retract the cryo shutter (by software control) should he/she wish to, e.g. continuous SEM monitoring, during the lift-out procedure.

-

Is it possible to perform SEM imaging while FIB milling with the cryo shutter in place?

No, however in practice this shouldn’t noticeably affect a user’s workflow. The majority of milling will take place with the shutter in place. Novice users who are more reliant upon their SEM imaging to monitor their progress during the final milling stages are able to manually retract the shutter for this short period of time.

Learn more about CERES from the brochure

-

The Ice Shield has a separate cooling system, so how long can you cool it for and how much nitrogen does it consume?

The CERES Ice Shield comes with its own liquid nitrogen (LN2) dewar that can provide 6 hours of cooling time on its own. Users can choose to refill manually. However, most users choose to use an auto-LN2-refiller connected to a large dewar to provide unlimited cooling time. *The large dewar is provided by the end users.

Didn't find an answer?

Fill in the form with your question, and our experts will get back to you soon!